- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

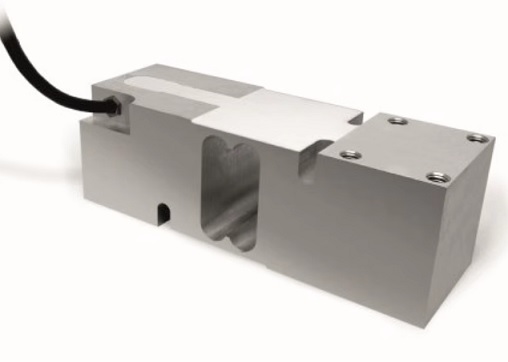

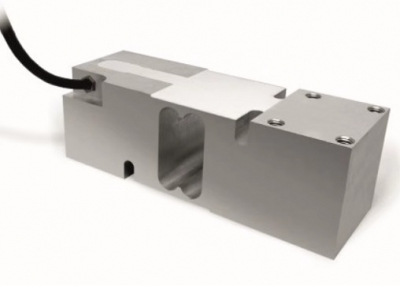

Cảm biến tải, cảm biến cân UTILCELL MOD220 0 - 75 - 100 - 150 - 200 - 250 - 300 - 500 - 635 kg

Cảm biến tải, cảm biến cân UTILCELL MOD220 0 - 75 - 100 - 150 - 200 - 250 - 300 - 500 - 635 kg

Tình trạng sản phẩm:

Basic characteristics of the sensor:

- Principle of double-cut single point force sensor

- Sensor capacity range: 50 - 75 - 100 - 150 - 200 - 250 - 300 - 500 - 635 kg

- Force sensor made of aluminum

- Accuracy class corresponds to 3000 pieces according to OIML

- High accuracy under eccentric loads

- IP67 protection (EN 60529)

-

Examples of use include:

- Platform enlarged to 600 x 600 mm

- Dosage scale

- counting scale

- Packaging and filling machines

-

-

| nominal weight | 50 - 75 - 100 - 150 - 200 - 250 - 300 - 500 – 635 | Kilogram |

| Precision class | 3000* | n. omr |

| small load | 0 | Percent Ln |

| workload | 150 | Percent Ln |

| safe load | 200 | Percent Ln |

| merge error | ±0.017 | % dream |

| Repeatability errors | ±0.01 | % Sean |

| Effect of temperature on zero | ±0.01 | %Sn/5°C |

| Effect of temperature on sensitivity | ±0.006 | %Sn/5°C |

| Ding Ling Error (30 minutes) | ±0.016 | % Sean |

| Compensation temperature | -10 to +40 | ℃ |

| Limit temperature | -20 to +70 | ℃ |

| nominal sensitivity | 2±10% | mV/V |

| nominally. Voltage | 10 | five |

| Supply voltage | 15 | five |

| input disorder | 415±15 | ohm |

| Output impedance | 350±3 | ohm |

| zero starting position | ±2 | % Sean |

| Insulation blocking | >5000 | Mom |

| Deformation (at Ln) | 0,3 – 0,5 | mm |

*The sensor corresponds to the accuracy category and does not have TC

-

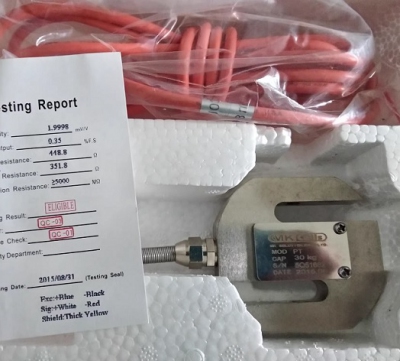

- Cảm biến tải, cảm biến cân TEDEA TEDEA 355 5kg, 250kg, 10kg, 500kg, 20kg, 50kg, 100kg, 200kg Liên hệ

-

- Cảm biến tải, cảm biến cân HARDY dynamic load cell ST02C 25kg, 50kg, 100kg, 200kg, 500kg, 1t, 1.5t, 2t Liên hệ

-

- Cảm biến tải, cảm biến cân, PT1000/PT8000 metal analog load cell mixing station batching scale vibration system cabinet Liên hệ

-

- Cảm biến tải, cảm biến cân, VPG REVERE TRANDUCERS 9123-500KG 9123-1000KG 9123-2000KG 9123-5000KG Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com