- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

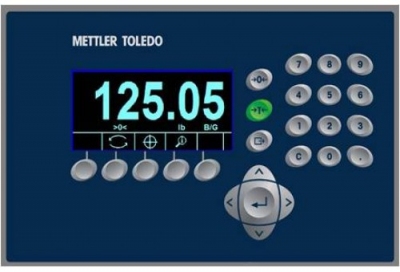

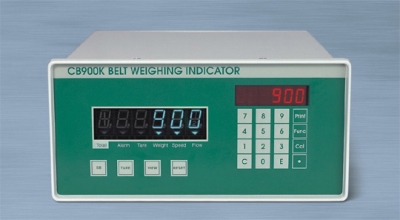

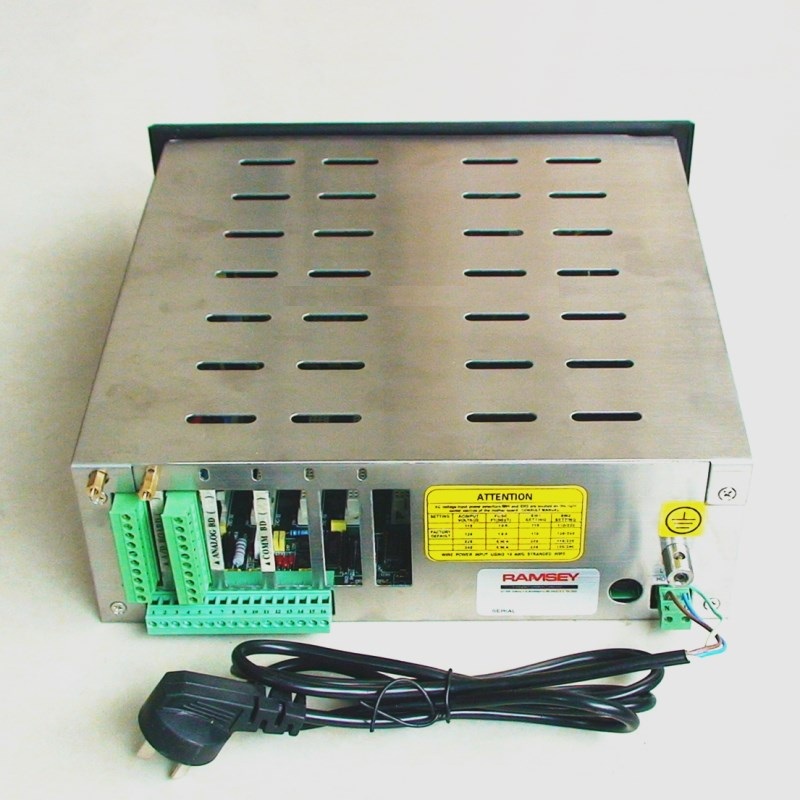

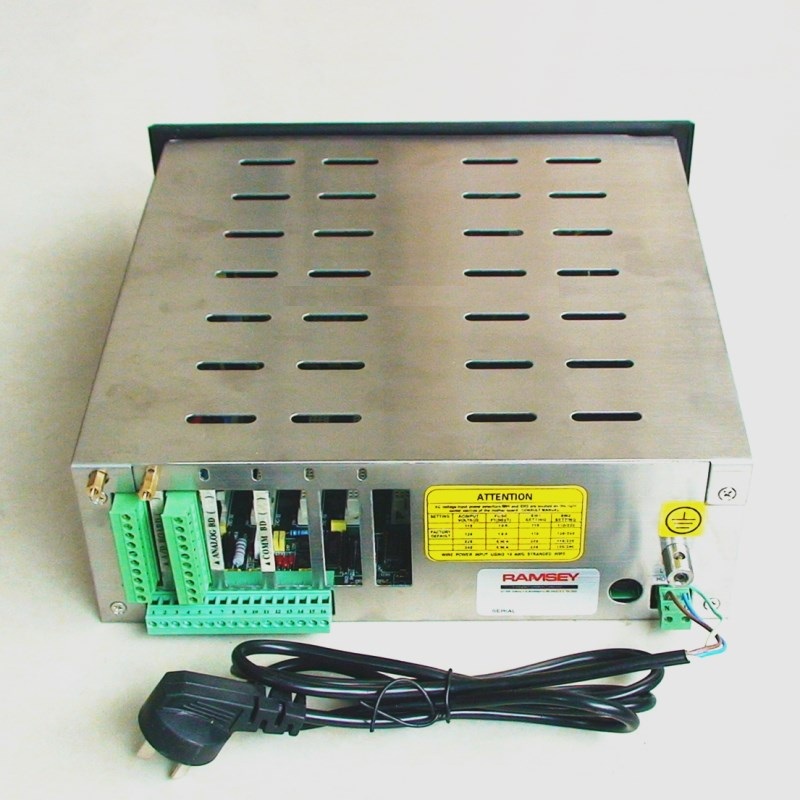

Bộ điều khiển hiển thị cân, weighing display controller, Ramsey MODEL2001, MODEL2105, MODEL2200, MODEL2101

MODEL2105/2101/2200/Weighing Instrument Belt Scale/Coiler/Feeder/Weighing Display Controller Belt Scale. Coal Feeder. Feeder Weighing Display Controller

The 2000 series models have 2001, 2101, 2105; RAMSEY2000 weighing instruments (integrator). Also known as weighing controller, Ramsey instrument, weighing integrator, totalizer, weighing instrument, MICRO-TECH, Ramsey MT2001, MT2105, MT2101, MT2301.MICRO-TECH2000, MICRO-TECH3000

The 2000 series models have 2001, 2101, 2105; RAMSEY2000 weighing instruments (integrator). Also known as weighing controller, Ramsey instrument, weighing integrator, totalizer, weighing instrument, MICRO-TECH, Ramsey MT2001, MT2105, MT2101, MT2301.MICRO-TECH2000, MICRO-TECH3000

- THƯƠNG HIỆU

Tình trạng sản phẩm:

000 series controllers, models are 2001, 2101, 2105; imported instruments are Thermo, RAMSEY2000 weighing instrument (integrator), BW100, BW500 integrator. Also known as weighing controller, Ramsey instrument, weighing integrator, totalizer, weighing instrument, MICRO-TECH, Ramsey MT2001, MT2105, MT2101, MT2301, MICRO-TECH2000, MICRO-TECH3000, etc. .

When the belt scale is used for metering settlement, the totalizer must ensure that the data is not arbitrarily changed and affect the accuracy of the belt scale. In the past, this was done by lead seal. Now if the belt scale adopts duplex communication or remote setting, the lead seal cannot be used. Ensure the safety of the totalizer. The Ramsey family uses a dedicated E2PROM memory. When the data (which can affect the accuracy) is changed, the memory automatically records the original data and the new change data. The result of the recording can not be changed manually, thus ensuring that the accuracy of the belt scale is not artificial. damage.

2001/2101 computer totalizer (domestic)

has the functions of automatic calibration, automatic zero adjustment, zero point automatic tracking, automatic correction interval, automatic diagnosis of faults, etc.;

alarm when the load of the belt conveyor system exceeds the limit; the

instrument can be digitized, processing the integral and accumulating It has excellent drift-free stability; it has a variety of data display and adjustable timing automatic printing, and is equipped with an almanac and date, which automatically displays instantaneous flow and accumulated flow. The printing time can be arbitrarily set by the user And has a power outage to maintain data function.

2105 weighing controller - weighing coal (material) machine dedicated

◆ comprehensive accuracy: ± 0.01%;

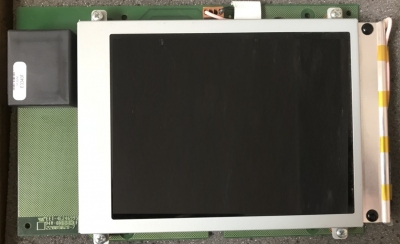

◆ high brightness liquid crystal display, showing instantaneous flow, cumulative amount, belt conveyor operating parameters; (highlighted VFT screen optional)

◆All Chinese scrolling menu operation, easy to operate;

◆Multiple calibration methods, automatic adjustment of zero point and interval, automatic zero tracking;

◆Remote counting adopts non-contact type, output AC or DC signal;

◆Current output interface (optional) ): It can output 0~20mA or 4~20mA current proportional to the flow rate;

◆Communication interface (optional): standard RS232C, RS485C interface; ◆Settable

flow rate, software PID adjustment, realize batching control;

◆Print interface (printer optional): Parallel printer. MODEL2105/2101/2200 weighing instrument belt scale coal feeder feeder weighing display controller

-

- Máy đo cân xe tải kỹ thuật số bằng thép không gỉ Keli D2008 XK3118K8 Bộ điều khiển hiển thị cân kỹ thuật số Liên hệ

-

- Màn hình hiển thị chống nước DPM-2.3, DPM-3, DPM-5, DPM-8 Keli 3 inch 5 inch hiển thị ngoài trời Màn hình LED màu đỏ Liên hệ

-

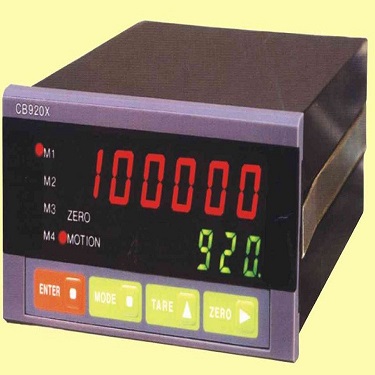

- Zhimei CB920X tốc độ cao bộ điều khiển cân hiển thị bộ điều khiển đóng gói thiết bị điều khiển cân đóng gói Liên hệ

-

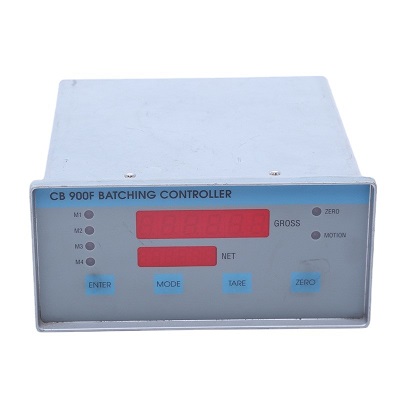

- Bộ điều khiển hiển thị cân Zhimei CB900F có tiêu chuẩn với cổng RS232 và đầu ra tương tự RS485 4-20mA tùy chọn Liên hệ

-

- Bộ điều khiển hiển thị cân thiết bị cân đóng gói Zhimei CB900P Bộ điều khiển hiển thị cân thành phần Liên hệ

-

- Bộ chuyển đổi tín hiệu cảm biến tải, chuyển đổi tín hiệu cân, CHIMEI weight transmitter PT350D Liên hệ

-

- Bộ chuyển đổi tín hiệu cảm biến tải, chuyển đổi tín hiệu cân, CHIMEI weight transmitter PT350C Liên hệ

-

- Bộ chuyển đổi tín hiệu cảm biến tải, chuyển đổi tín hiệu cân, TR200H weighing transmitter 4-20MA/0-10V/0-5V Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com