- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

Bộ hiển thị cân CB920X-10 automatic batching weighing display controller

Bộ hiển thị cân CB920X-10 automatic batching weighing display controller

Tình trạng sản phẩm:

● Analog-to-digital conversion up to 200 times per second

● Display accuracy up to 1/15000

● Optional RS485 as standard serial output and input port

● Multi-point communication can be achieved through RS485 device

● Starting conditions for batching can be set through the menu

● Automatic removal of ingredients The skin condition can be set through the function table.

● It can be set to automatically return to zero when power is turned on.

● The net weight display holding function of the ingredients can be set through the function table.

● The overshoot range can be set to ensure that the automatic compensation function does not cause errors due to mechanical failure

. Delay time can be set for slow speed control.

● The number of control comparisons can be set to ensure that automatic control does not cause erroneous control due to impact on the weighing body.

● The delay time for starting tare removal can be set.

● The number of tare removal detections can be set to prevent the weighing body from being accidentally Taring errors may occur under stable conditions.

● Fast and slow speed prohibition comparison times can be set independently.

● The temperature coefficient is less than (&lusmn;0.0008% of reading + 0.3 digits)/℃.

● Equipped with dual digital filtering.

● Dosing quantity is lower than the tolerance. When adding ingredients, you can add ingredients

● Equipped with a dosing function to make the ingredients faster and more accurate

● Use an easy-to-detach socket

● Display accuracy up to 1/15000

● Optional RS485 as standard serial output and input port

● Multi-point communication can be achieved through RS485 device

● Starting conditions for batching can be set through the menu

● Automatic removal of ingredients The skin condition can be set through the function table.

● It can be set to automatically return to zero when power is turned on.

● The net weight display holding function of the ingredients can be set through the function table.

● The overshoot range can be set to ensure that the automatic compensation function does not cause errors due to mechanical failure

. Delay time can be set for slow speed control.

● The number of control comparisons can be set to ensure that automatic control does not cause erroneous control due to impact on the weighing body.

● The delay time for starting tare removal can be set.

● The number of tare removal detections can be set to prevent the weighing body from being accidentally Taring errors may occur under stable conditions.

● Fast and slow speed prohibition comparison times can be set independently.

● The temperature coefficient is less than (&lusmn;0.0008% of reading + 0.3 digits)/℃.

● Equipped with dual digital filtering.

● Dosing quantity is lower than the tolerance. When adding ingredients, you can add ingredients

● Equipped with a dosing function to make the ingredients faster and more accurate

● Use an easy-to-detach socket

-

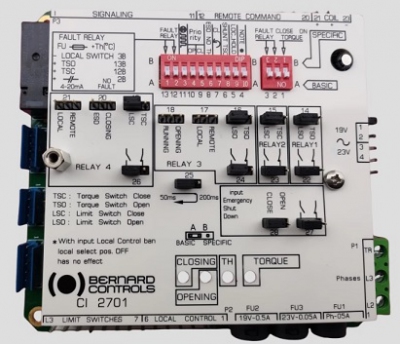

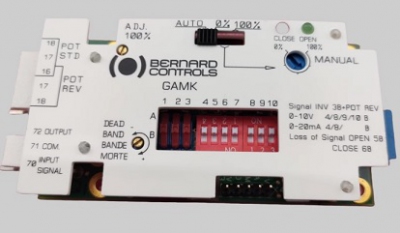

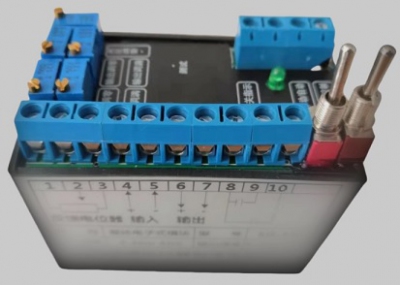

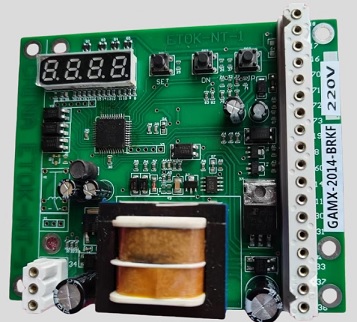

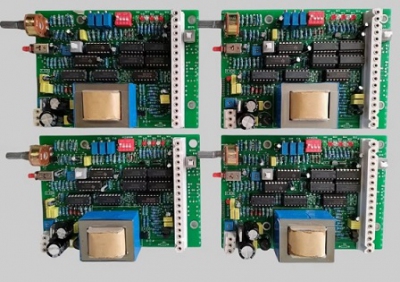

- Mạch điều khiển cho van actuator GAMX-2014-BRKF Electric Actuator Control Board GAMX-2014-BRKF 380V GAMX-2014-BRKF 220V Liên hệ

-

- Mạch điều khiển cho van actuator GAMX-2015CP Electric Actuator Control Board GAMX-2015CP 220V GAMX-2015CP 380V Liên hệ

-

- Mạch điều khiển cho van actuator GAMX-TD518S Electric actuator control board GAMX-S518S GAMX-L1840 Liên hệ

-

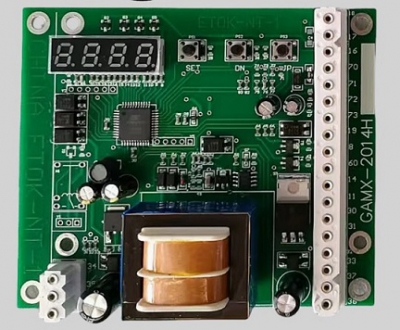

- Mạch điều khiển cho van actuator GAMX-2014H Electric Actuator Control Board GAMX-2014H 220V GAMX-2014H 380V Liên hệ

-

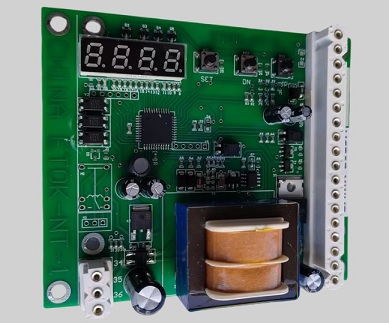

- Mạch điều khiển cho van actuator GAMX-2013H Electric Actuator Control Board GAMX-2013H 220V GAMX-2013H 380V Liên hệ

-

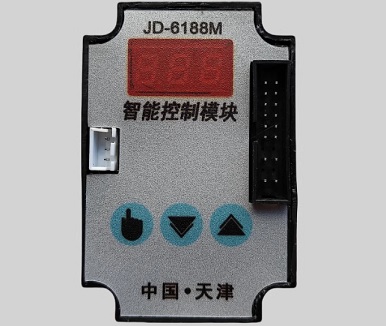

- Mạch điều khiển cho van actuator JD-6188M Intelligent Control Module Electric Actuator Controller Liên hệ

-

- Mạch điều khiển cho van actuator IDM-WR-C Intelligent Positioning Module Electric Actuator Controller Liên hệ

-

- Mạch điều khiển cho van actuator BND-DZ Intelligent Electric Actuator Intelligent Control Module Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com