- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

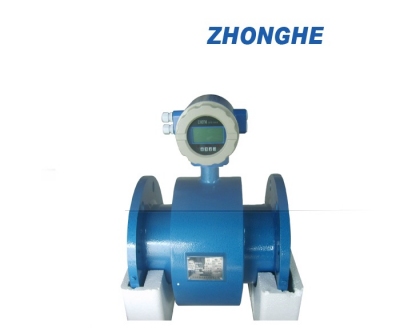

Đo lưu lượng,LDG intelligent electromagnetic flowmeter water

Tình trạng sản phẩm:

ntelligent electromagnetic flowmeter

The intelligent electromagnetic flowmeter consists of two parts: a sensor and a converter. It is based on Faraday's law of electromagnetic induction and is used to measure the volumetric flow of conductive liquid with conductivity greater than 5μS/cm . It is an inductive instrument for measuring the volumetric flow of conductive media. In addition to measuring the volumetric flow rate of general conductive liquids, it can also be used to measure the volumetric flow rate of strong corrosive liquids such as strong acid and alkali, and uniform liquid-solid two-phase suspension liquids such as mud, slurry and pulp.

Widely used in petroleum, chemical, metallurgy, textile, paper, environmental protection, food and other industrial sectors and municipal management, water conservancy construction, river dredging and other fields of flow measurement.

One. Features:

1. Full digital processing, strong anti-interference ability, reliable measurement, high precision, flow measurement range up to 150 : 1

2. Ultra-low EMI switching power supply, suitable for wide range of power supply voltage and goodanti- EMI performance.

3. The use of 16 -bit embedded microprocessor, computing speed , high precision, low-frequency square wave excitation frequency is programmable, improve the stability of the measured flow rate and low power consumption.

4. The use of SMD components and surface mount (SMT) technology, circuit reliability.

5. There are no moving parts in the pipe, no flow blocking parts, and there is almost no additional pressure loss in the measurement.

6. On-site can modify the range online according to the actual needs of the user.

7. Measurement results are independent of physical parameters such as flow velocity distribution, fluid pressure, temperature, density, and viscosity.

8. High-definition backlit LCD display, full Chinese menu operation, easy to use, easy to operate, easy to learn and understand.

9. With digital communication signal output such as RS485 , RS232 , Hart and Modbus . ( optional )

10. With self-test and self-decision function.

11. Total hourly recording function, recording the total amount of flow in hours, suitable for time-sharing measurement ( optional )

12. There are three internalizers to display the forward cumulative amount reverse cumulative amount and the difference integrated amount respectively. The internal set is not powered down, and 16 times of power down time can be recorded . ( optional )

13. Infrared handheld operator, 115KHZ communication rate, long-distance non-contact operation converter all functions ( optional )

Two . Technical parameters:

Range selection:

three. Electrode selection:

The material of the electrode should be selected according to the corrosiveness of the fluid to be tested. Please check the relevant manual for corrosive tests on special fluids.

four. Selection of lining materials:

The lining material should be selected according to the corrosive wear and temperature of the tested medium.

Electromagnetic flowmeter integrated and split type selection

Integrated electromagnetic flowmeter: the sensor and converter are integrated.

Split type electromagnetic flowmeter: The split type electromagnetic flowmeter consists of a sensor and a converter. The sensor is installed on the measuring pipe. The converter is installed within 30 meters or within 100 meters of the sensor , and the two are connected by a shielded cable.

Under the conditions of better on-site environment, an integrated electromagnetic flowmeter is generally used.

The split electromagnetic flowmeter is generally selected in the following cases:

1. Ambient temperature or flowmeter converter surface is exposed to radiation temperatures greater than60 °C .

2. Where the pipe vibration is large.

3. Where the aluminum shell of the converter is severely corrosive.

4. Where the site has high humidity or corrosive gas.

5. The flowmeter is installed in an occasion where it is inconvenient to debug at high altitude or underground.

(The split electromagnetic flowmeter should indicate the cable connection distance between the sensor and the converter when ordering, generally no more than 20M , and the converter is wall mounted. )

The intelligent electromagnetic flowmeter consists of two parts: a sensor and a converter. It is based on Faraday's law of electromagnetic induction and is used to measure the volumetric flow of conductive liquid with conductivity greater than 5μS/cm . It is an inductive instrument for measuring the volumetric flow of conductive media. In addition to measuring the volumetric flow rate of general conductive liquids, it can also be used to measure the volumetric flow rate of strong corrosive liquids such as strong acid and alkali, and uniform liquid-solid two-phase suspension liquids such as mud, slurry and pulp.

Widely used in petroleum, chemical, metallurgy, textile, paper, environmental protection, food and other industrial sectors and municipal management, water conservancy construction, river dredging and other fields of flow measurement.

One. Features:

1. Full digital processing, strong anti-interference ability, reliable measurement, high precision, flow measurement range up to 150 : 1

2. Ultra-low EMI switching power supply, suitable for wide range of power supply voltage and goodanti- EMI performance.

3. The use of 16 -bit embedded microprocessor, computing speed , high precision, low-frequency square wave excitation frequency is programmable, improve the stability of the measured flow rate and low power consumption.

4. The use of SMD components and surface mount (SMT) technology, circuit reliability.

5. There are no moving parts in the pipe, no flow blocking parts, and there is almost no additional pressure loss in the measurement.

6. On-site can modify the range online according to the actual needs of the user.

7. Measurement results are independent of physical parameters such as flow velocity distribution, fluid pressure, temperature, density, and viscosity.

8. High-definition backlit LCD display, full Chinese menu operation, easy to use, easy to operate, easy to learn and understand.

9. With digital communication signal output such as RS485 , RS232 , Hart and Modbus . ( optional )

10. With self-test and self-decision function.

11. Total hourly recording function, recording the total amount of flow in hours, suitable for time-sharing measurement ( optional )

12. There are three internalizers to display the forward cumulative amount reverse cumulative amount and the difference integrated amount respectively. The internal set is not powered down, and 16 times of power down time can be recorded . ( optional )

13. Infrared handheld operator, 115KHZ communication rate, long-distance non-contact operation converter all functions ( optional )

Two . Technical parameters:

| Nominal diameter (mm) (Special specifications can be customized) | Pipeline PTFE lining: DN10 ~ DN600 | |

| Pipeline rubber lining: DN40 ~ DN1200 | ||

| Flow direction: | Positive, negative, net flow | |

| Range ratio: | 150 : 1 | |

| Repeatability error: | ±0.1% of the measured value | |

| Accuracy level: | Pipeline: 0.5 grade 1.0 stage | |

| Measured medium temperature: | Ordinary rubber lining: - 20 ~ +60 °C | |

| High temperature rubber lining: - 20 to +90 °C | ||

| PTFE lining: - 30 ~ +100 °C | ||

| High temperature PTFE lining: - 20 to +180 °C | ||

| Fixed work stress: (High pressure can be customized) | DN6 - DN80 : ≤1.6MPa | |

| DN100 - DN250 : ≤ 1.0MPa | ||

| DN300 - DN1200 : ≤0.6MPa | ||

| Flow rate range: | 0.1 - 15m/s | |

| Conductivity range: | The conductivity of the measured fluid is ≥5μs/cm | |

| Current output: | Load Resistance | 0 to 10 mA : 0to 1.5 kΩ |

| 4 to 200mA : 0 to 750 kΩ | ||

| Digital output frequency: | The upper limit may be . 1 ~ 5000HZ between | |

| Digital output mode: | Set transistor open-circuit bidirectional output with photoelectric isolation in the output frequency | |

| Collector maximum current: | When the external power supply is ≤35V , the maximum current of the collector is 250mA. | |

| Power supply: | AC220V or DC24V | |

| Required straight pipe length | Upstream ≥5DN , downstream ≥2DN | |

| Connection method: | Flange connection between flowmeter and piping | |

| Connection size: | Flange dimensions shall comply with the GB11988 provisions | |

| Explosion-proof grade: | mdIIBT4 | |

| Protection level: | IP65 , special order up to IP68 | |

| Ambient temperature: | - 25 to +60 °C | |

| Relative temperature: | 5% to 95% | |

| Total power consumption: | Less than 20W | |

| Signal output | 4-20mA ( load 0-750Ω) , pulse / frequency, control level |

| Power supply | AC220V , tolerance 15% ; or DC24V , ripple ≤5% |

| Communication output | RS 485 , MODBUS protocol, HART protocol, Profibus-DP protocol |

| Inner diameter (mm) | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 |

| Qmin(m3/h) | 0.0283 | 0.0636 | 0.12 | 0.176 | 0.29 | 0.452 | 0.7 | 1.19 |

| Qmax(m3/h) | 4.24 | 9.54 | 16.96 | 26.5 | 43.42 | 67.85 | 106.0 | 179.0 |

| Inner diameter (mm) | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| Qmin(m3/h) | 1.8 | 2.82 | 4.41 | 6.36 | 11.3 | 17.6 | 25.4 | 34.6 |

| Qmax(m3/h) | 271.0 | 424.0 | 662.0 | 954.0 | 1690 | 2650 | 3810 | 5190 |

| Inner diameter (mm) | 400 | 450 | 500 | 550 | 600 | 700 | 800 | 900 |

| Qmin(m3/h) | 45.2 | 57.2 | 77.6 | 85.5 | 101.0 | 138.0 | 180.0 | 229.0 |

| Qmax(m3/h) | 6780 | 8570 | 10600 | 12800 | 15200 | 20700 | 27100 | 34300 |

| Inner diameter (mm) | 1000 | 1100 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

| Qmin(m3/h) | 282.0 | 342.0 | 407.0 | 554.1 | 732.7 | 916.0 | 1131.0 | 1368.4 |

| Qmax(m3/h) | 42400 | 51300 | 61000 | 83121 | 108566 | 137404 | 169635 | 205258 |

The material of the electrode should be selected according to the corrosiveness of the fluid to be tested. Please check the relevant manual for corrosive tests on special fluids.

| material | Code | Corrosion resistance |

| 316L stainless steel | V | 1 Suitable for industrial, domestic water, raw water well water, urban sewage and other neutral solutions 2 weakly corrosive acid, alkali, salt medium such as carbonic acid, acetic acid, etc. |

| Hastelloy C | HC | 1 Suitable for oxidation resistant acids such as nitric acid, mixed acid, a mixture of chromic acid and sulfuric acid 2 corrosion resistance of oxidation-resistant salts or other oxidant environments such as Fe , Cu 3 Excellent corrosion resistance to seawater, alkaline solution and oxide solution 4 not applicable: hydrochloric acid |

| Hastelloy B | HB | 1 good corrosive to non-oxidizing acids, alkalis, salts such as sulfuric acid, phosphoric acid, hydrofluoric acid 2 not applicable: nitric acid |

| titanium | Ti | Resistant to seawater, various chlorides, hypochlorite and various hydroxides |

| 钽 | Ta | In addition to hydrofluoric acid, it is almost resistant to corrosion by all chemical media. But expensive |

| platinum | Pt | Suitable for all acid and alkali salt solutions (fuming sulfuric acid and nitric acid) |

| Tungsten carbide | W | Excellent wear resistance, designed for abrasive media such as mud and pulp |

The lining material should be selected according to the corrosive wear and temperature of the tested medium.

| Lining material | Corrosion resistance | Operating temperature | Scope of application |

| Neoprene Ne | Resistant to general low concentration acid and alkali corrosion | -20 to 70 °C | Industrial water sewage low concentration acid-base salt |

| Polyurethane rubber PO | Excellent wear resistance, specially designed for strong abrasive slurry, not resistant to corrosion | -10 to 60 °C | Liquid containing solid particles (cement slurry, etc.) |

| Polyfluoroethylene propylene FEP | 1 heat and corrosion resistance is equivalent to PTFE 2 high mechanical strength, good wear resistance 3 The inner surface is smooth and it is not easy to adhere to sediment 4 has good negative pressure resistance, anti-vacuum effect | -40 to 180 °C | All fluids except strong abrasive media such as mortar. LikePTFE , it can be used for hygienic media such as beverages. |

| PTFE PTFE | Almost resistant to corrosion from all chemical media, poor wear resistance | -40 to 180 °C | Cannot be used in negative pressure piping and highly abrasive fluids |

Integrated electromagnetic flowmeter: the sensor and converter are integrated.

Split type electromagnetic flowmeter: The split type electromagnetic flowmeter consists of a sensor and a converter. The sensor is installed on the measuring pipe. The converter is installed within 30 meters or within 100 meters of the sensor , and the two are connected by a shielded cable.

Under the conditions of better on-site environment, an integrated electromagnetic flowmeter is generally used.

The split electromagnetic flowmeter is generally selected in the following cases:

1. Ambient temperature or flowmeter converter surface is exposed to radiation temperatures greater than60 °C .

2. Where the pipe vibration is large.

3. Where the aluminum shell of the converter is severely corrosive.

4. Where the site has high humidity or corrosive gas.

5. The flowmeter is installed in an occasion where it is inconvenient to debug at high altitude or underground.

(The split electromagnetic flowmeter should indicate the cable connection distance between the sensor and the converter when ordering, generally no more than 20M , and the converter is wall mounted. )

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com