- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

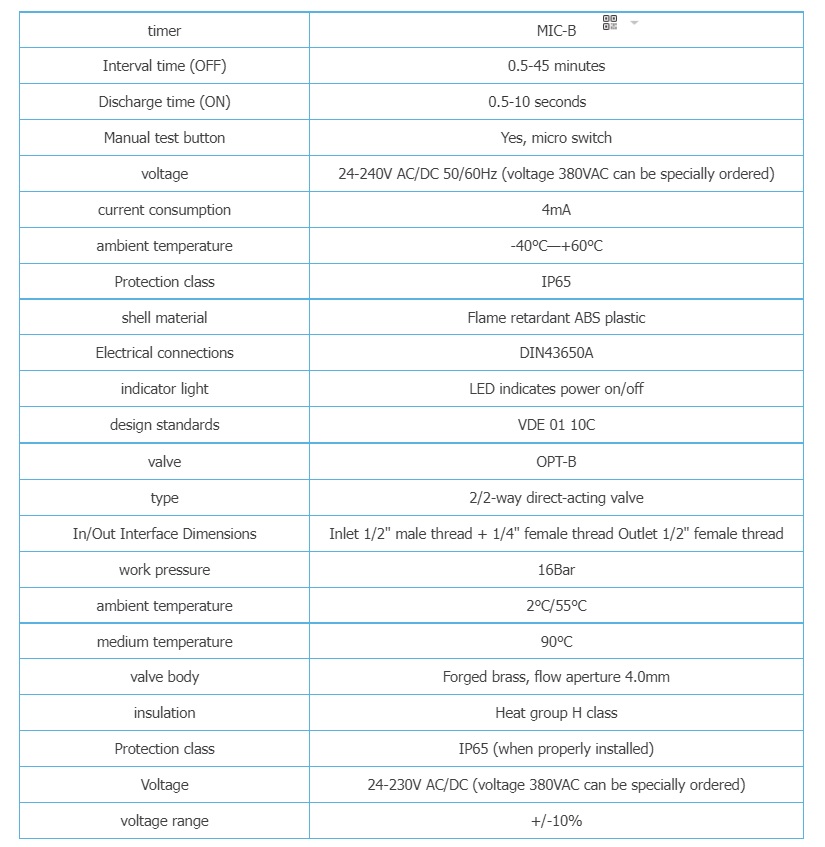

Van xả nước tự động automatic drain JORC MIC-A, MIC-B / AC230V

Tình trạng sản phẩm:

Electronic drain valve concise instruction manual:

1. Installation

1. Purge and clean the compressed air system before installation

2. Pay attention to the arrow direction of the valve body during installation: do not use hoses that are not resistant to airflow impact at the water outlet

3. The power supply voltage should be consistent with the drain valve voltage: when using DC , The positive pole must be connected to the connector "1"

4. The drain valve of the cable has been connected at the factory, brown is fire red L, blue is zero line N, yellow and green two colors are safety grounding line GND

5. Be sure to tighten the long cable on the junction box. Screws to prevent water from burning Warning! When installing the electronic drain valve, it must be ensured that: 1. The compressed air has been evacuated (ie at zero pressure) 2. The power supply has been cut off

2. Timer setting

1. The

left knob of the timer sets the discharge time, and the right knob sets the interval time ; First set the discharge time to 2S, the interval time to 20min, and then make further adjustments as needed.

2. Digital timer

(1) After long press (OFF) for 3 seconds, the last set time SEC ON (MIN OFF) will be displayed. and flashes, after release, the time decreases by one unit each time the ON key is pressed, and the time increases by one unit each time the OFF key is pressed. After setting the required ON (OFF) time, press the TEST/ENTER key to save the data and exit. Setting state, after the setting is completed, the system returns to the original working state, and the new time set will take effect in the next cycle (2) Time query and manual test

In normal working state, such as when the current state is ON (OFF), press Press the OFF (ON) key to display the time set in the OFF (ON) state, and switch to the OFF (ON) working state.

In the normal working state, press the TEST/ENTER key and release it, and then switch to the next initial state , that is, the ON state, the ON light is on, the power supply is output and the timing is re-timed, that is, it can be used as a manual test button

. 3. Abnormal state handling

1. The electronic drain valve operates normally, but no water is discharged. It is likely that the filter is blocked, and it needs to be cleaned. Filters; filters are cleaned at least once a month

2. When the components are not damaged, the solenoid valve cannot be closed (air leakage). The reason may be that a large amount of powder in the condensate penetrates into the filter screen and enters the gap between the valve core and the sheath, and the valve core is clamped.

3. Clean the valve core; (

1) Close the isolation valve, press the TEST key to empty the compressed air, and ensure that the drain valve has been isolated from the air pressure system (zero pressure)

(2) Cut off the power supply of the drain valve

( 3) Remove the coil (before removing the coil, the electronic drain valve must be de-energized, otherwise the energized coil will burn after being separated from the valve stem), unscrew the hexagon nut, take out the valve core and spring, and clean the valve seat, valve core and spring And the valve core sheath, and then reinstall the MIC-A universal electronic drain valve to match the analog circuit solid-state electronic timer with the solenoid valve to realize the timing and automatic discharge of the condensed water in the compressed air system. MIC-A type electronic drainage valve is widely used in compressed air system components such as precision filter end drainage, separator, dryer, air storage tank, dripping foot, etc. The discharge time and interval can be adjusted according to different needs.

The MIC-B universal electronic drain valve is matched with an analog circuit solid-state electronic timer and a solenoid valve to realize the timing and automatic discharge of the condensed water in the compressed air system. MIC-B type electronic drain valve is widely used in compressed air system components such as filters, separators, dryers, air storage tanks, dripping feet, etc. The discharge time and interval can be adjusted according to different needs.

characteristic:

● Holland JORC company technology, joint venture products, high quality, excellent price

● One model suitable for all applications, simple installation, automatic, maintenance-free

●

Adjustable interval time and discharge time and testbuttonoptions

● Explosion - proof valveis available

● CE certification, patented product, protection grade IP65, insulation class

H Type structure Dimensions: 122×93×97mm, weight 600g

-

- Van điện từ AOPON 304302K.03.01(220V) 304302K.03.02 (24V) 304302K.04.01T(220V) 304302K.04.02T(24V) 304302.3/2.01T(220V) 304302.3/2.02T(24V) 304302.2/3.01HZ (220V) 304302.2/ Liên hệ

-

- Cuộn hút van điện từ đường kính lỗ lỗ 13mm 14mm 16mm 19mm 20mm 23mm 26mm 31.5mm, điện áp cuộn hút 12VDC, 24VDC, 110VAC 220VAC, loại chân đứng chân kim 10mm, 17mm Liên hệ

-

- Van thủy lực Jiangnan hydraulic solenoid valve reversing valve 24D-10B 24D-25B 24D-63B 24E-10B 24E-25B 24E-63B 24D2-10B 24D2-25B 24D2-63B 24E1-10B 24E1-25B 24E1-63B 24E2-10B 24E2-25B 24E2-63B Liên hệ

-

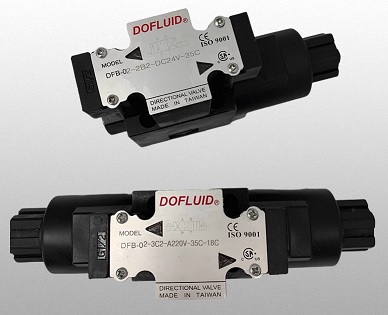

- Van thủy lực DOFLUID solenoid valve DFB-02-3C2-DC24V-35C DFB-02-3C2-A220V-35C DFB-02-3C4-DC24V-35C DFB-02-3C4-A220V-35C DFB-02-2B2-DC24V-35C DFB-02-2B2-A220V-35C DFB-02-3C60-DC24V-35C DFB-02-3C60-A220V-35C DFB-02-2D2-DC24V-35C DFB-02-2D2-A220V-35C Liên hệ

-

- Van thủy lực KOMPASS D4-02-2B2 3C2 3C60 3C3 solenoid valve D5-G03-3C4 D4-02-2B2 D4-02-3C2 D4-02-3C4 D4-02-3C3 D4-02-3C5 D4-02-3C6 D4-02-2B3B Liên hệ

-

- Van thủy lực D5-02-3C4/3C2/3C3/3C6/2D2 KOMPASS solenoid valve D5-02-3C2 D5-02-3C4 D5-02-3C3 D5-02-3C6 D5-02-3C5 D5-02-2D2 D5-02-2B2 Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com